Machining Process

In order to follow the product from the first machining to the last one, we decided to install in our facility few 3-axis and 5-axis milling machines, and turning machines too, month by month the request of the market convinced us to redouble the capacity of production, so the quantity of machines is going to increase in the next period.

The company is structured in oder to follow the market, and flexibility is one of our main characteristics.

Assembling Process

Assembling and delivering

high quality finished wheels

CAD-CAM-FEM Analysis

Our target is to offer the highest quality wheel in the shortest time possible,so we can design a wheel in less than 24 hours,taking advantage of the most advanced drawing softwares which assure us a perfect machining and an enormous control of all the processes. As a matter of fact our computers, exploiting the latest technologies, are directly connected with the mechanical machines and we can carefully supervise them during the all machining.

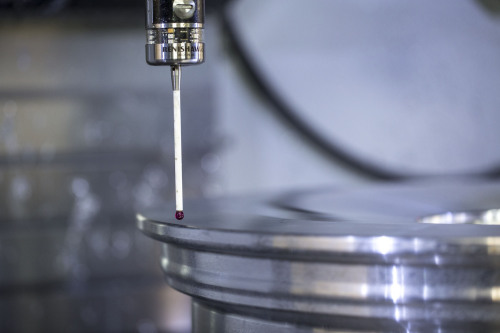

Quality

Our quality controls start from the alluminium billet to the finished wheels

Evrything is controlled during production

Finishing Process

We can make

many finishes

of the highest level